STANDARD FEATURES:

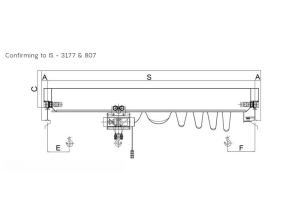

Design: Compact dimensions, easy to operate and easy to maintain, modular design with direct fitment at Tie beams or any supporting structure.

Structure: Radio graphed butt welded joints ensure defect free safe rigid structure. The material of construction confirms to IS 2062 & the Bridge designed for minimum vibrations.

Motors: Crane uses sturdy cylindrical/conical rotor pole-changing motors with elegant continuous cast aluminum sections, integrated safety brakes insulation class F, IP 54 protection, S4, Crane Duty.

Gear boxes: Precision helical/ spur gear units with case-hardened gears, high-grade surface treatment and permanent oil/grease lubrication

Brakes: Electromagnetic DC Disc brakes featuring automatic braking on power failure (fail safe).

Electrical panel: Modular design, covering a very wide operating range. The systems are designed for ease of installation and maintenance as well as reliable operation, with fuse-less circuitry, ducted wiring and non-screwed terminals. Each drive group is equipped with a motor overload protection device to provide effective protection against inadmissible overloading.

Painting: Every component & part is thoroughly scrubbed & painted with two coats of primer before assembly & two coats of synthetic enamel after testing.

SOME SPECIAL & OPTIONAL FEATURE:

• Limit switches to prevent over hoisting & over lowering of hook

• Light weight Push button stations, handy, easy to operate, PVC unbreakable.

• Variable frequency drives.

• Limit switches & brakes in C.T & L.T Motions,

• Radio Remote controls for wireless controls.

INDUSTRIAL SEGMENTS:

• Construction industry

• Cement industry

• Steel Plants

• Paper Plants

• Chemical Plants

• Dock YardsTop of Form

• Plastic Moulding Units.

TECHNICAL SPECIFICATIONS :

| Model | S.W.L. (M.T) | Span (mtrs.) (S) | Head Room (mm) (C) | Wheel Base (mm) | Hook Approach (mm) E/F | End Clearance (mm) A | Wheel Load Per Wheel (Approx) | Weight of Crane Kgs (Approx) |

| GSG-1 | 1 | 8 12 16 20 |

650 750 800 850 |

1600 2400 3200 4000 |

700 700 700 700 |

200 200 200 200 |

1000 1200 1400 1775 |

1700 2500 3250 4700 |

| GSG-2 | 2 | 8 12 16 20 |

750 800 850 900 |

1600 2400 3200 4000 |

750 750 750 750 |

200 200 200 200 |

1600 1850 2000 2400 |

2000 2900 3800 5200 |

| GSG-3 | 3 | 8 12 16 20 |

800 850 900 1100 |

1600 2400 3200 4000 |

850 850 850 850 |

200 200 200 200 |

2200 2450 2650 3125 |

2500 3500 4300 6200 |

| GSG-5 | 5 | 8 12 16 20 |

800 900 1000 1100 |

1600 2400 3200 4000 |

950 950 950 950 |

250 250 250 250 |

3400 3725 4000 4450 |

2900 4200 5300 7100 |

| GSG-7.5 | 7.5 | 8 12 16 20 |

850 1000 1100 1200 |

1600 2400 3200 4000 |

1000 1000 1000 1000 |

250 250 250 250 |

4850 5200 5650 6100 |

3600 5100 6700 8500 |

| GSG-10 | 10 | 8 12 16 20 |

900 1000 1200 1300 |

1600 2400 3200 4000 |

1100 1100 1100 1100 |

250 250 250 250 |

6350 6750 7200 7500 |

4400 6000 7800 9300 |

| GSG-15 | 15 | 8 12 16 20 |

1000 1100 1250 1400 |

1600 2400 3200 4000 |

1200 1200 1200 1200 |

250 250 250 250 |

9500 9850 10300 10800 |

6200 7600 9600 12000 |

NOTE:

• Above specifications are for Class II Medium Duty Cranes

• Above dimensions are foe Cranes having 6 Mtr. Lift. There may be minor deviations in dimensions for higher height of Lift.

• ‘Globe’ reserve the right to effect any designs or dimensional charges without Notice.